CASE STUDY

PROCESSOL STRIPPER

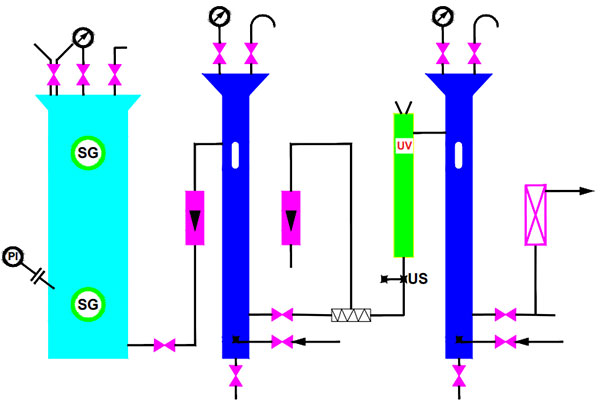

PROCESSOL developed unique design to remove the Low boil COD based on the Hanery’s constant of mass transfer and wet air oxidation method. At high temperature solvent / heavy organic matter get oxidize in presence of the oxygen and catalyst into degradable form and further physiochemically treated to get desired COD. The unoxidized solvents carry over with the air and condensed in the chiller, recovered as hydrocarbon. This hydrocarbon contains minimal moisture.

PROCESSOL Stripper can be used as pre / post treatment of MEE. The System designed with heat integration to optimize steam consumption.

The reactor is a bubble column; it is coupled after the heat exchanger with the separation of the effluent and the off gases. Since the oxidation reactions are exothermic, sufficient energy may be released in the reactor to allow the wet oxidation system to operate less additional heat input it depends on the organic compound of the feed.

Specific advantages and disadvantages

PROCESSOL Stripper performs good results for the low boiling VOC as well Complex Organic Matters. High pressure and High temperature operation is recommended. Further Physio -Chemical treatment / Biological treatment may require achieving desired COD level.

Operating Cost calculation

- For 70 kld Feed flow having 10% solvent

- Feed = 3500 Kg/hr with @10% solvents, Feed inlet temperature 60 deg C (Condensate Temp)

- Energy required to heat feed till 150 deg C = 3500 x 1 x (150-60) = 315000 kcal/hr

- 50 % heat will be recovered with the heat exchanger.

- Steam required to heat feed till 150 deg C = (315000/2) / 540 = 292 kg/hr

- Total Steam Cost = 292 x 2.50 x 20 = 14600 Rs/day (Steam cost 2.50 Rs / Kg)

- Chiller Operating Cost = 70 Kw x 8 x 20 = 11200 Rs / Day

- Air Compressor KW / Cost = 25 kw x 8 x 20 = 4000 Rs

- Physio Chemical Treatment cost = 7000 Rs. / Day (Assumed- Rs. 100/KL)

- Heat recovery @ 30% = (-4380) Rs. / Day

- Total Operating Cost=14600+11200+4000+7000-4380=32420 Rs/Day=0.46 Rs/L

COMPARISON SUMMARY

Sr.Direct Steam Stripper (DSS)Column Distillation Stripper (CDS)Multi Effect Stripper (MES) PROCESSOL Stripper

| 1 | Removes Solvent / VOC up to Azeotrope level. | Removes Solvent / VOC with suitable reflux ratio. | Effectively Removes Solvent / VOC by Air stripping and Wet Air Oxidation. |

| 2 | Used to treat MEE feed | Can be used to treat MEE feed as well MEE condensate | Can be used to treat MEE feed as well MEE condensate |

| 3 | Effective for Solvents bellow 80 DegC BP | Effective for consistent Solvent type and ratio | Effective for any Solvent as it strips and oxidize |

| 4 | Ammoniacal Nitrogen remains with top/bottom | Ammoniacal Nitrogen remains with top/bottom | Ammoniacal Nitrogen removed with condensate |

| 5 | Considerable Condensate Qty. Contains high water contents, needs to be incinerated. | Moderate Condensate Qty. at high reflux ratio. Contains high water contents needs to be incinerated. | Very Low Condensate Qty. contains low water contents, can be sold / recycled / incinerated. |

| 6 | Operating Cost (Rs/L) 0.91 | Operating Cost (Rs/L) 0.86 | Operating Cost (Rs/L) 0.46 |

| 7 | System used by specific industries | System commonly used now. Suppliers doesn’t give performance guarantee. | Tailor made design required Pilot study for suitability. |

| 8 | COD load in Stripper as well MEE condensate. | COD load in Stripper as well MEE condensate. | Permissible COD load in MEE condensate. For low TDS / High COD effluent, MEE can be eliminated. |